Maintenance Mobile Elevated work platforms

The Best Practice Guidelines (BPG) for MEWP has just been given an overhaul. The underlying reason being that: accidents involving MEWP use in New Zealand have, and continue to result in fatalities and serious harm injuries.

Overturning of machines, being catapulted or falling from machines, being crushed between the basket/ structures, electrocution and collision with other plant and vehicles are just a few examples of unfortunate yet preventable accidents and injuries. The causes of these accidents have included inadequate training and supervision, equipment failure, not following the manufacturer’s recommendations and not fully assessing the hazards and risks associated with the job site and equipment.

The new Guidelines have been developed to help improve workplace health and safety by providing information for the design, safe use and proper maintenance of mobile elevating work platforms (MEWPs), and cover the safe work practices that assist duty holders to meet their obligations under the HSE Act and the pending Reform Act. The BPG is a generic guide, and is not industry specific. For example there is a separate Best Practice Guidelines for the Safe Use of Elevating Work Platforms in the Horticultural Industry that has recently been released by Worksafe NZ.

Here’s how we as Suppliers, operators, hirers, and trainers of EWP’s can prepare ourselves for these important new changes.

Employers and Principals should familiarise themselves with new operator training competency and compliance requirements for EWP training. The guideline lists a means of competency by way of training “through nationally recognised MEWP NZQA unit standards or an overseas equivalent or higher qualification”. Following training the employer or principal must ensure by way of instruction and supervision that the operator is competent on the actual machine they intend on using.

The new guideline also references Unit standards 23229 and 17600 as means of compliance for work at height involved in operating EWP’s. The table below from the BPG identifies the NZQA unit standards that pertain to the 5 EWP machine types.

Note: The guidelines now require refresher training to be undertaken every 3 years (instead of 5).

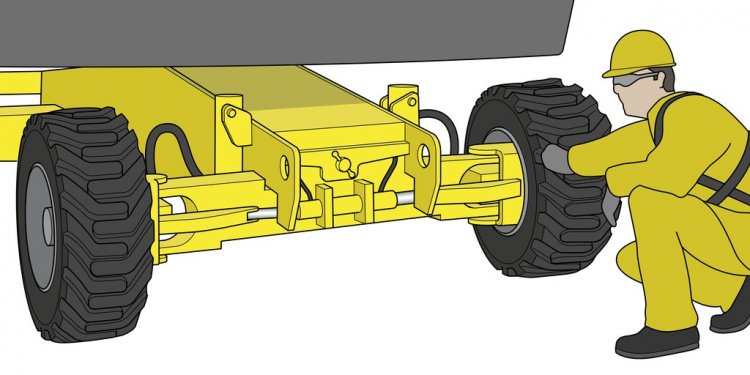

A readily available MEWP logbook must be used to record pre-operational inspections, routine inspections and maintenance. The visual inspection and functional test is carried out before operation and include the items listed in the operator’s manual or a pre-ordained check sheet. All MEWP are subject to a 3 monthly routine inspection. Other certifications include the six monthly operational and manufacturers maintenance check and the 10 yearly “Major Inspection”. If a machine is modified, damaged or involved in an accident the EWP must be recertified. Duty holders must satisfy themselves that an inspection is carried out by a competent person. Employers, owners, suppliers and duty holders must recognise that simply receiving an inspection certificate is NOT sufficient compliance and does not fulfill their obligations with the guidelines.

Safety ‘n Action undertake EWP NZQA level training throughout New Zealand and are able to provide information and assistance with compliance around the MEWP best practice guidelines. We are proud to have worked alongside Worksafe NZ and industry stakeholders in the development of the pending MEWP Best Practice Guideline. Visit our website safetynaction.co.nz.

We Learn Best When Teaching Is Tailored To Our Learning Style.

Safety ‘n Actions blended learning approach embraces that.Every individual learns in a slightly different way. Some of us learn best by hearing, some by seeing information as pictures, others by reading words, and of course those who prefer to learn by actively ‘doing’. One size does not fit all, especially when you need every individual to apply their skills quickly and practically in their own working environment. Whether working face-to-face with our trainers, or practicing your new skills high in the air in real-life EWP scenarios, the goal at Safety ‘n Action is to keep our training accessible and engaging for everyone involved.

Can we change our attitude towards safety in New Zealand?

As New Zealander’s, we have a typical “she’ll be right” attitude that can often translate to our workplace. Subsequently, we have one of the worst records of workplace injury and death in the Western world. If an improved approach toward occupational health and safety is not readily embraced we are at risk large financial repercussions or, even worse, more workforce injuries and deaths. Whether we like it or not, Health & Safety in the workplace is set to become a bigger part of our working lives. It’s not all bad when everyone gets to return home at the end of each day.